Our Latest Large Rearing House Project

We are pleased to show off our latest poultry rearing house project, and take you through all of the phases involved in our turnkey farming solutions.

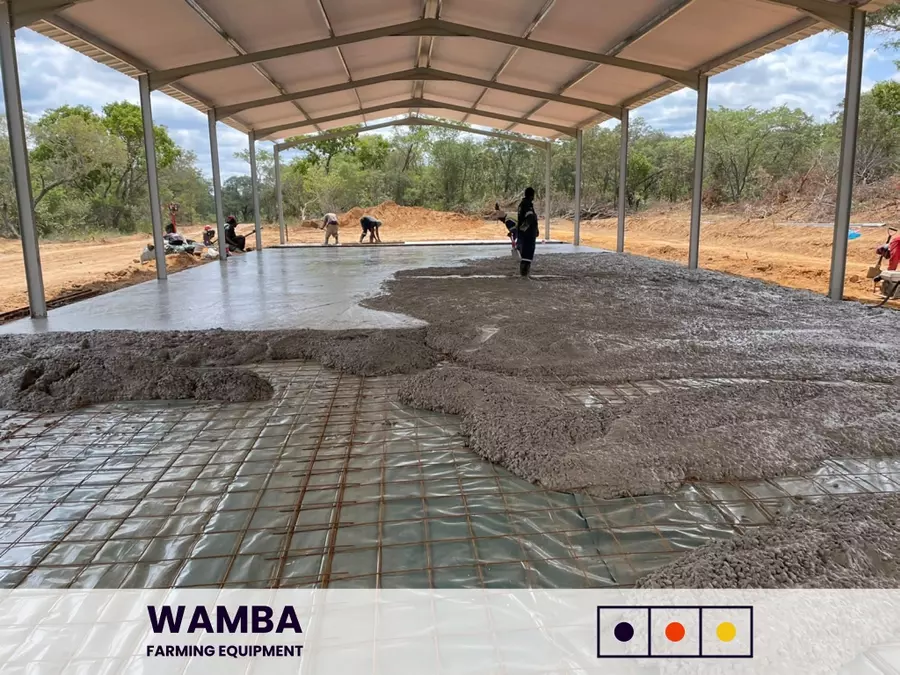

Phase 1 – Groundwork

Starting with groundwork. Bush cleared, ground prepared, wet, and compacted to prepare the structure and concrete.

Phase 2 – Steelwork

Our in-house steel team performs all the Steelworks. I-beams are prepared at our headquarters, transported, and assembled on-site. This house is 117m x 10m.

Phase 3 – Wetwork and Sheeting

Things move quickly on-site! A plastic USB green liner and 193 6mm mesh reinforcements were laid down. Concrete is poured, power floated, and finally, expansion joints are cut.

Phase 4 – Brickwork

Here, the pit for the manure belt is completed, and the side walls around the house are being built. This acts as the foundation for the panels.

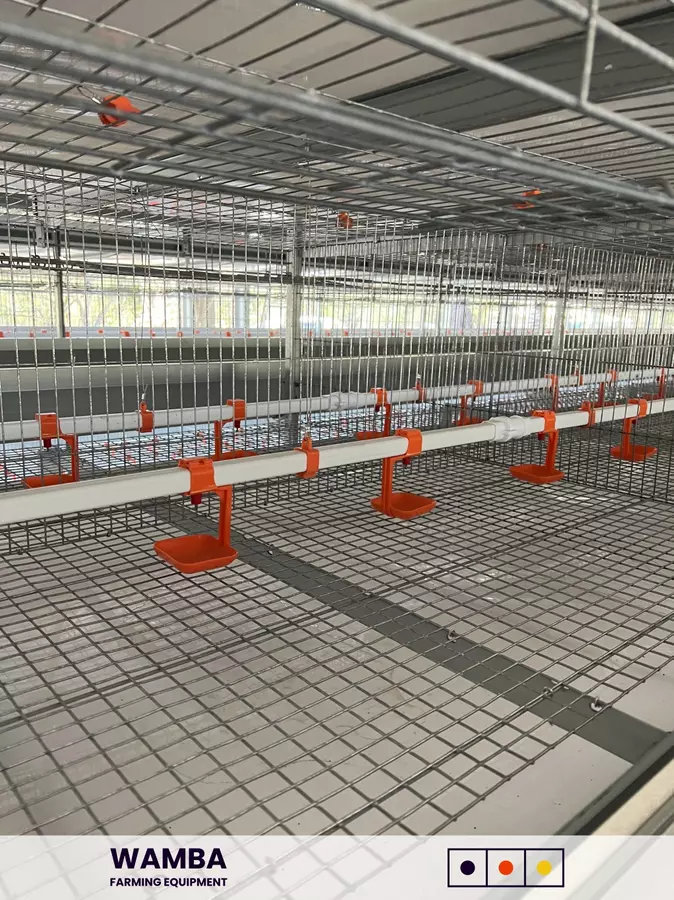

Phase 5 – Cage installation

H-frame pullet cages are installed by starting from the back and laying out the necessary parts. Our equipment is strong and durable, with lots of extra reinforcements and wiring.

Phase 6 – Water System

The water system goes up, and the drinking line is mounted with a drip cup to avoid water spilling onto the manure belt.

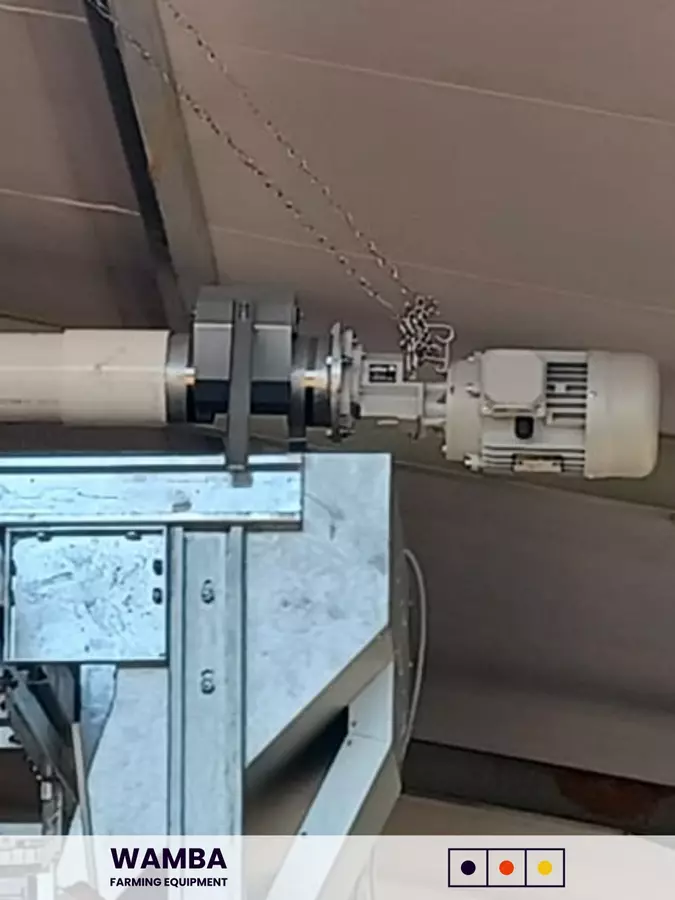

Phase 7 – Manure Removal

The manure removal system is being installed here. It comprises high-efficiency motors, PU material with long service life, and well-designed rubber-coated driving roller and sectional rubber-coated tensioning rollers making sure that the belt has less manure sticking to it.

The manure scraper is designed to protect the pp conveyor belt with a double scraper for optimal cleaning effect.

Phase 8 – Automated Feed System

This automated feed delivery system has a hot galvanized zinc silo, driving systems, PVC tubes, and augers. All are designed to ensure that optimal management and production are achieved.

The feed distributor makes allowance for 1-day old chicks all the way up to point of lay. It specializes in feeding uniformly for weight uniformity and can refresh the feed. At this point, our hard-working team has almost completed the project.